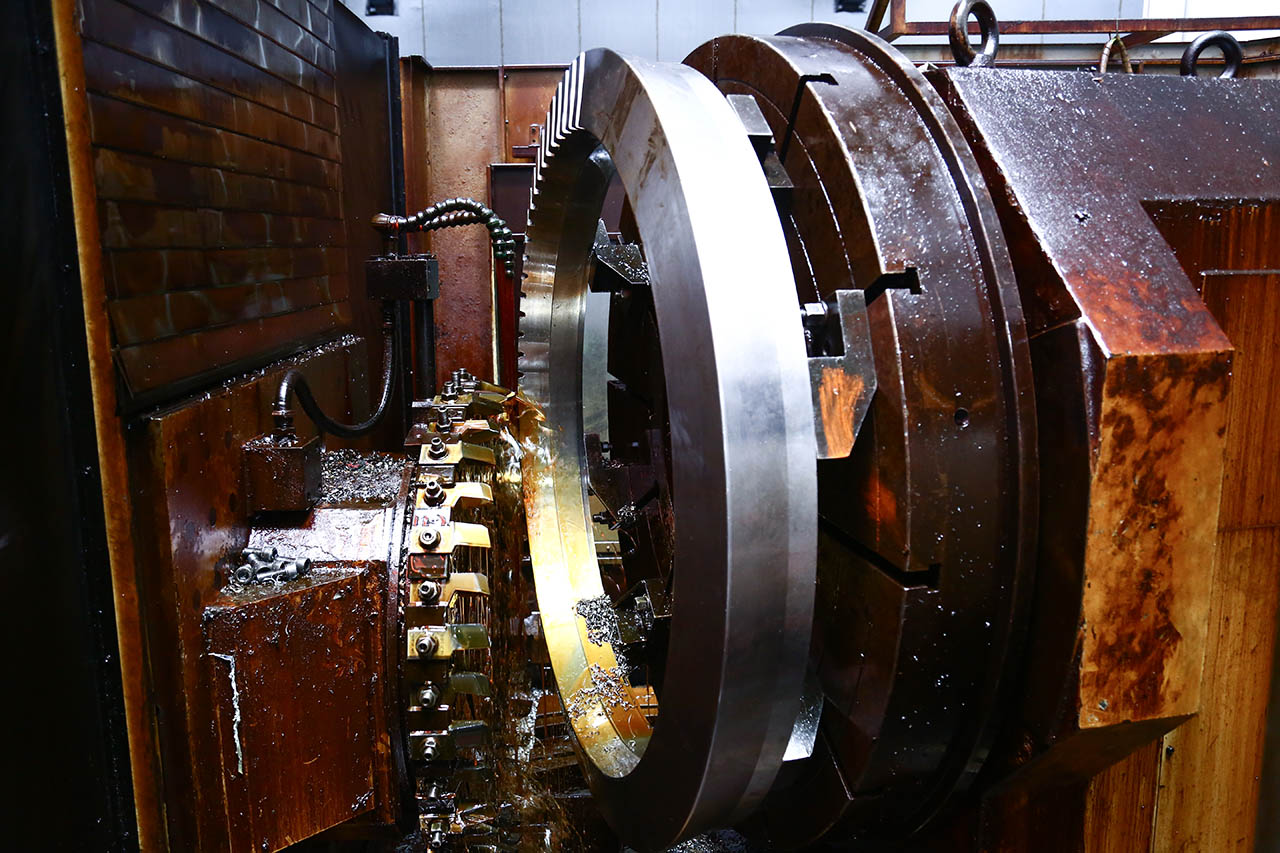

Spiral Bevel Gear Milling

Spiral bevel gear is bevel gear with curved, oblique teeth to provide gradual engagement and larger contact surface and less noise. Bevel gears can be generally classified by their manufacturing methods, namely the Gleason method and Klingelnberg method.

Applications: Mining Crusher, Vertical Roller Mill, Drilling Rotary Table, High Speed Train

Module (mn): 40, max

Both Gleason and Klingelnberg teeth profile are available.

Outside Diameter (Do): Ф2000mm (Milling) Max

Ф1600mm (Ground) Max

Material: 17CrNiMo6/ 18CrNiMo7, 18Cr2Ni4WA

Heat Treatment: Normalized, Quenching &Tempering, Nitriding, Carburizing

Process: Teeth shaping, Teeth grinding

Accuracy grade:

Unground, Q9 GB or equivalent Q9 AGMA

Ground, Q5 GB or equivalent Q13 AGMA